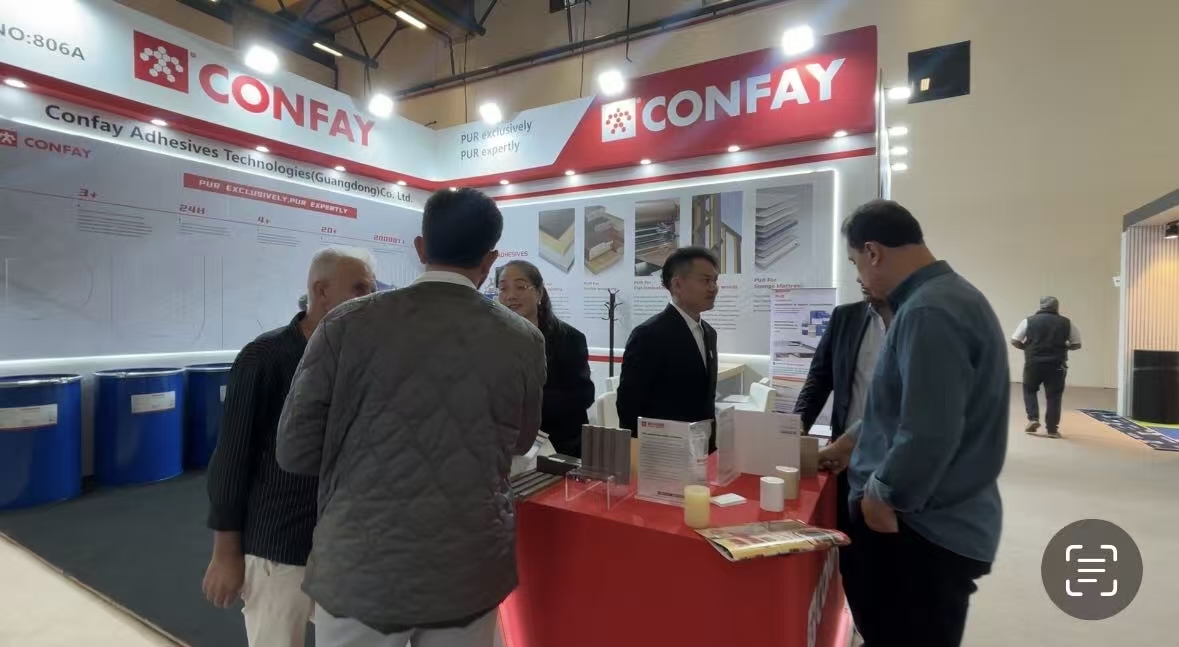

At INTERMOB 2025, Confay, a leading PUR hot melt adhesive manufacturer, presented groundbreaking bonding solutions to the global woodworking industry. We focused on addressing critical challenges in outdoor and high-end furniture manufacturing, where our PUR hot melt adhesive products garnered significant attention for their exceptional weather resistance and structural strength. As a specialized PUR hot melt glue factory, we offer not only high-performance hot melt adhesive but also comprehensive technical collaboration. Confay's advanced polyurethane reactive glue technology is redefining the standards of strength and elegance in woodworking, empowering manufacturers to create more durable and refined products. Visit us to explore tailored solutions and request samples for your specific applications.

2025-10-30

More