How to Choose the Right PUR Hot Melt Adhesive for Woodworking? 5 Key Indicators

In the woodworking industry, the quality of bonding processes directly impacts the durability and aesthetics of final products. In recent years, PUR hot melt adhesive (polyurethane reactive hot melt adhesive) has become the preferred bonding material for high-end woodworking due to its excellent performance and environmental characteristics. However, with numerous products and suppliers in the market, how does one select the most suitable PUR hot melt adhesive for woodworking applications? This article details 5 key indicators to help you make an informed decision.

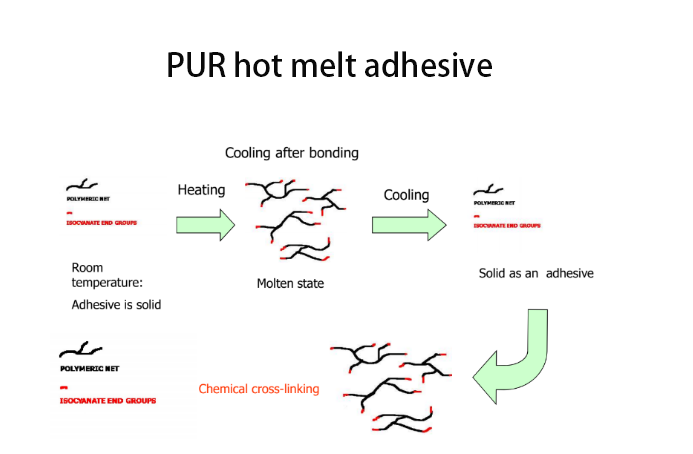

What is PUR Hot Melt Adhesive?

Polyurethane reactive hot melt adhesive is a single-component, solvent-free hot melt adhesive that forms an irreversible cross-linked structure through reaction with environmental moisture. This unique curing mechanism combines the quick initial tack of traditional hot melts with the high strength and weather resistance of reactive adhesives, making it particularly suitable for wood processing, furniture manufacturing, and interior decoration.

5 Key Indicators for Selecting PUR Hot Melt Adhesive

1. Bonding Strength and Durability

Bonding strength is the primary indicator for measuring the performance of PUR hot melt adhesive. High-quality products should provide consistent and lasting adhesion, ensuring wood products don't experience glue failure or delamination during long-term use.

Initial adhesion: PUR hot melt adhesive rapidly solidifies after application, providing sufficient initial strength for subsequent processing.

Final bond strength: After complete curing, the bond strength should significantly exceed that of the wood itself, ensuring joint integrity.

Environmental resistance: Excellent PUR hot melt adhesive should withstand temperature variations, humidity fluctuations, and UV exposure while maintaining long-term stability.

When selecting, be sure to request detailed technical data sheets from the PUR hot melt adhesive manufacturer and conduct practical tests to ensure the product meets your application requirements.

2. Open Time and Curing Speed

Open time refers to the window during which bonding operations can still be performed after adhesive application, while curing speed determines production line efficiency and output capacity.

Open time: Woodworking applications typically require sufficient open time for part adjustment and alignment. Choose products with appropriate open time (usually 3-10 minutes) to balance operational flexibility and production efficiency.

Curing speed: In high temperature and humidity environments, PUR hot melt adhesive cures faster. Communicate with your PUR hot melt glue factory to select products with curing characteristics matched to your production environment.

3. Viscosity and Rheological Properties

Viscosity directly affects application ease and adhesive penetration, which is particularly important for porous materials like wood.

Viscosity at application temperature: PUR hot melt adhesive is typically applied at 110-140°C. Within this temperature range, viscosity should be low enough to ensure good flow and wettability, but not so low as to cause excessive flow or deep penetration into the wood.

Rheological properties: High-quality PUR hot melt adhesive should exhibit appropriate thixotropy - easy flow during application but maintaining shape without dripping after application ceases.

4. Environmental and Safety Characteristics

With growing environmental awareness, selecting low-emission, hazardous substance-free PUR hot melt adhesive has become an industry trend.

VOC emissions: Ensure selected products meet international environmental standards such as REACH and CARB with low volatile organic compound (VOC) emissions.

No isocyanate residue: While PUR hot melt adhesive contains isocyanate groups before curing, there should be no free isocyanate residue after complete curing, ensuring use safety.

Certifications and compliance: Prioritize products from PUR hot melt adhesive manufacturer with ISO 9001, ISO 14001, and other system certifications.

5. Supplier Technical Support and After-sales Service

Reliable suppliers provide not only high-quality products but also professional technical support and comprehensive after-sales service.

Technical support: Reputable PUR hot melt glue factory will provide detailed application guidance including dispensing parameters, equipment recommendations, and troubleshooting.

Customization capability: Suppliers should offer customized product solutions based on your specific requirements.

Supply chain stability: Ensure suppliers have stable production capacity and complete logistics systems to guarantee timely delivery.

Advantages of Global PUR Hot Melt Adhesive Supply Chain

The global supply chain for PUR Hot Melt Adhesives offers significant advantages for international woodworking businesses:

Competitive manufacturing efficiency: Leading PUR hot melt adhesive manufacturer operations worldwide provide cost-effective solutions without compromising quality

Technical innovation access: Global suppliers invest heavily in R&D, ensuring access to the latest advancements in adhesive technology

Supply chain resilience: Diversified manufacturing bases across different regions ensure supply continuity and risk mitigation

Standardized quality: International manufacturers maintain consistent quality standards across global production facilities

How to Choose the Right International Supplier

When selecting a global PUR hot melt adhesive supplier, consider these steps:

Define requirements clearly: Determine specific PUR hot melt adhesive requirements based on your woodworking applications (such as solid wood bonding, edge banding, or lamination)

Identify potential suppliers: Find reputable PUR hot melt glue factory options through industry exhibitions, professional media, or peer recommendations

Request samples and testing: Obtain samples from multiple suppliers for comparative testing under actual production conditions

Evaluate comprehensive capabilities: Consider the supplier's technical strength, quality consistency, pricing structure, and after-sales service

Establish long-term partnership: Select the supplier that best meets your needs and establish a stable long-term partnership

Conclusion

Selecting the appropriate Polyurethane reactive hot melt adhesive is crucial for the quality and value of woodworking products. By focusing on these 5 key indicators - bonding strength, open time, viscosity properties, environmental safety, and supplier support - you can make an informed choice.

With the advancement of PUR Hot Melt Adhesives in the global market, internationally manufactured PUR hot melt adhesives have become reliable choices for the worldwide woodworking industry. Whether you're a small woodworking shop or a large furniture manufacturer, you can find suitable PUR hot melt adhesive products and suppliers that meet your needs.

Remember, the best PUR hot melt adhesive isn't the most expensive or cheapest option, but the one most suited to your specific application and production conditions. Investing time in evaluation and testing, and choosing the right bonding solution, will significantly enhance your woodworking product quality and market competitiveness.

Have Any Adhesive Questions ? Please kindly feel free to contact us for more information.

More than 10 years of experience to answer your questions!