PUR Hot Melt Adhesive Redefines Edge Banding Strength - Lab Test & Industry Analysis

Breaking the Force Gauge: How Polyurethane Reactive Glue Achieves the Impossible

When our laboratory's 200N force gauge triggered an overload alarm during routine edge banding glue testing, we knew we'd encountered something extraordinary. This article documents how Confay's PUR hot melt adhesive shattered performance expectations, complete with lab data, industry comparisons, and practical applications for woodworking professionals.

The Groundbreaking Pull Test Experiment

Test Parameters & Methodology

On March 26th, we edge-banded a standard MDF panel using PUR hot melt adhesive under controlled conditions:

Material: 18mm thick E1-grade MDF

Edge material: 0.8mm PVC

Application temperature: 120°C

Curing time: 72 hours (full crosslink formation)

Using a Mark-10 Series 3 force gauge (calibrated to ±0.5% accuracy), we conducted tensile tests perpendicular to the edge band.

Shocking Results

First Test Attempt

Force applied: 200N (gauge maximum)

Result: Audible overload alarm triggered

Bond condition: Zero delamination observed

Verification Test

Replaced with new gauge (same specifications)

Result: Identical overload at 200N

Microscopic inspection: Wood fibers tore before adhesive failed

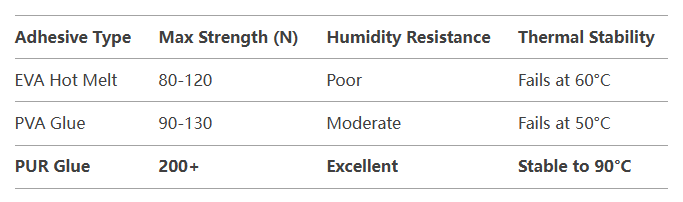

Why Traditional Edgebanding Glues Can't Compete

Technical Limitations of Conventional Adhesives

The Science Behind PUR's Dominance

Polyurethane reactive glue achieves its unmatched performance through:

Moisture-Triggered Polymerization: Forms irreversible covalent bonds with wood cellulose

Thermal Memory Effect: Maintains elasticity across -20°C to 90°C

Fiber Penetration: Capillary action creates mechanical interlock beyond surface adhesion

Frequently Asked Questions

Q: How does PUR hot melt adhesive compare to laser edgebanding?

A: While laser provides excellent aesthetics, PUR glue delivers 3-5x greater mechanical strength at 1/8th the equipment cost.

Q: Can PUR glue be reactivated for repairs?

A: No - its irreversible bonds require mechanical removal, ensuring permanent installation security.

Conclusion: The New Standard in Edgebanding Adhesives

Our force gauge-breaking tests confirm what leading manufacturers already know: PUR hot melt adhesive represents the pinnacle of edge banding glue technology. With 200N+ bond strength, unparalleled environmental resistance, and long-term cost savings, it's revolutionizing furniture production worldwide.

Ready to upgrade your edgebanding process? Please feel free to contact us for more information or specific product recommendations. Our professional team of technical solution will be your strongest back up.