Analysis of the High Temperature and Water Resistance of PUR Hot Melt Adhesive: Why It’s the Top Choice for the Woodworking Industry?

Introduction

In the woodworking industry, the choice of adhesive significantly impacts product quality and durability. While traditional EVA-based hot melt adhesive (HMA) is widely used, its performance in high-temperature and water-resistant applications is limited. In contrast, PUR hot melt adhesive (PUR HMA) has emerged as the preferred choice for high-end wood manufacturing due to its superior properties. This article delves into the heat and water resistance of PUR hot melt adhesive and explores why it is increasingly favored by manufacturers of furniture, wooden doors, cabinets, and more.

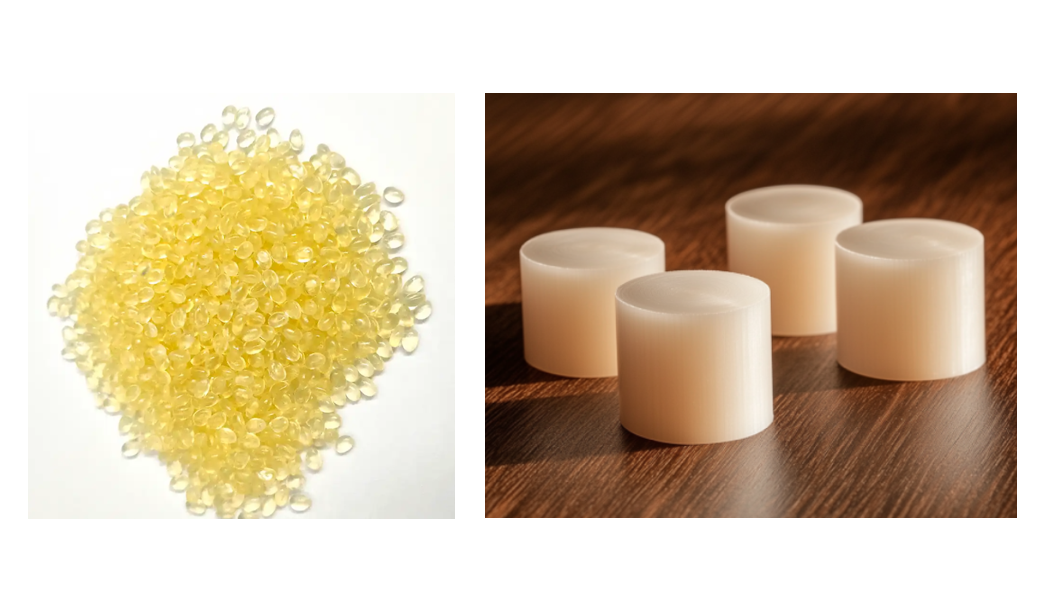

1. What is PUR Hot Melt Adhesive?

PUR hot melt adhesive (Polyurethane PUR Hot Melt Adhesive) is a reactive polyurethane-based adhesive. Unlike conventional hot melt adhesives, it undergoes a secondary cross-linking reaction with moisture in the air after cooling, forming stronger chemical bonds that enhance adhesion and durability.

Key Advantages of PUR Hot Melt Adhesive:

Exceptional heat resistance (withstands -40°C to 120°C)

Superior water resistance (ideal for humid environments)

Strong bonding strength (suitable for wood, composites, and more)

Eco-friendly & low VOC (complies with EU environmental standards)

2. Heat Resistance of PUR Hot Melt Adhesive

2.1 Limitations of Traditional EVA Hot Melt Adhesives

Standard hot melt adhesive (e.g., EVA-based) tend to soften under high temperatures, leading to bond failure. For example:

Car interiors can exceed 70°C in summer, causing EVA adhesives to weaken.

Kitchen cabinets exposed to heat may experience adhesive deformation.

2.2 High-Temperature Performance of PUR Hot Melt Adhesive

PUR hot melt adhesive forms a 3D cross-linked network, ensuring stability even in extreme heat:

Wide temperature range: -40°C to 120°C, with short-term resistance up to 150°C (e.g., during drying processes).

Anti-thermal creep: Minimal softening under prolonged heat exposure.

Ideal for high-heat applications: Wooden flooring with underfloor heating, automotive interiors, outdoor furniture, etc.

2.3 Real-World Applications

Wooden doors: PUR adhesive remains intact even in summer heat.

Kitchen cabinets: Resists steam and heat near stovetops.

Automotive wood trim: Adapts to temperature fluctuations inside vehicles.

3. Water Resistance of PUR Hot Melt Adhesive

3.1 Why Does Woodworking Require Waterproof Adhesives?

Wood absorbs moisture, causing conventional adhesives to:

Turn white or crack

Lose bonding strength

Promote mold growth (e.g., in bathrooms and kitchens)

3.2 How PUR Hot Melt Adhesive Resists Water

Once cured, PUR hot melt adhesive forms a hydrophobic structure that repels moisture:

Cross-linking reaction: Bonds irreversibly with ambient humidity.

Low water absorption: 80% less than EVA adhesives.

Remains strong even when submerged: Suitable for bathroom vanities, marine furniture, etc.

3.3 Real-World Applications

Bathroom cabinets: Resists mold in humid conditions.

Outdoor wood structures: Withstands rain and dew.

Engineered wood flooring: Prevents warping under heated floors.

1. Why is PUR Hot Melt Adhesive the Preferred Choice in Woodworking?

4.1 Comparison with Traditional Adhesives

Property | PUR HMA | EVA HMA | PVA Glue |

Heat Resistance | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

Water Resistance | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

Curing Speed | ★★★★☆ | ★★★★★ | ★☆☆☆☆ |

Eco-Friendliness (Low VOC) | ★★★★★ | ★★★☆☆ | ★★☆☆☆ |

4.2 Industry Trends

High-end furniture makers: Increasingly switching to PUR hot melt adhesive.

Automated production: PUR adhesives are ideal for machine application, improving efficiency.

Environmental regulations: Solvent-based adhesives are being phased out in favor of PUR, which meets RoHS/REACH standards.

4.3 How to Choose High-Quality PUR Hot Melt Adhesive?

Source from reputable PUR hot melt adhesive manufacturers (e.g., Henkel, H.B. Fuller, Confay or leading domestic suppliers).

Test for heat resistance, water resistance, and aging performance.

Select the right PUR adhesive formulation based on wood type (solid wood, MDF, plywood, etc.).

5. Conclusion

Thanks to its outstanding heat resistance, waterproof properties, and superior bonding strength, PUR hot melt adhesive (Polyurethane PUR Hot Melt Adhesive) is rapidly becoming the go-to adhesive in the woodworking industry. Whether for high-end furniture, wooden doors, cabinets, or outdoor structures, PUR adhesive delivers long-lasting and reliable performance.

If you are a woodworking manufacturer or furniture brand, partnering with a trusted hot melt adhesive manufacturer to source high-quality PUR adhesive can significantly enhance your product’s competitiveness!

Please feel free to contact us if you have any query. Thanks.