Curing Mechanism of PUR Hot Melt Adhesive:

How Does It Achieve Ultra-Strong Bonding?

Introduction

In modern industrial production, bonding technology plays a crucial role, and hot melt adhesive (HMA) is widely used due to its fast curing, eco-friendliness, and non-toxicity. Among them, PUR hot melt adhesive (polyurethane reactive hot melt adhesive) stands out for its superior bonding strength and durability, making it the preferred choice for high-end bonding applications. But what is the curing principle of PUR hot melt adhesive? How does it achieve ultra-strong bonding? This article will delve into its curing mechanism and explore its applications across various industries.

1. What is PUR Hot Melt Adhesive?

PUR hot melt glue (polyurethane reactive hot melt adhesive) is a special type of hot melt adhesive. Unlike traditional HMAs, it melts when heated, is applied in liquid form, and then cures through a reaction with moisture in the air, forming an extremely strong bond. Its main component is polyurethane hot glue, which offers excellent heat resistance, chemical resistance, and impact resistance.

Due to its unique curing mechanism, PUR hot melt adhesive is widely used in automotive manufacturing, electronics, furniture assembly, packaging, and more. Many PUR hot melt adhesive manufacturers continuously optimize formulations to meet diverse industrial needs.

PUR hot melt adhesive

PUR hot melt adhesive

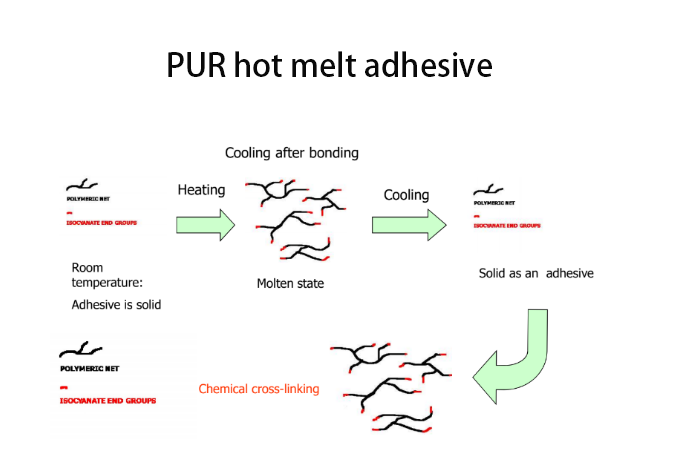

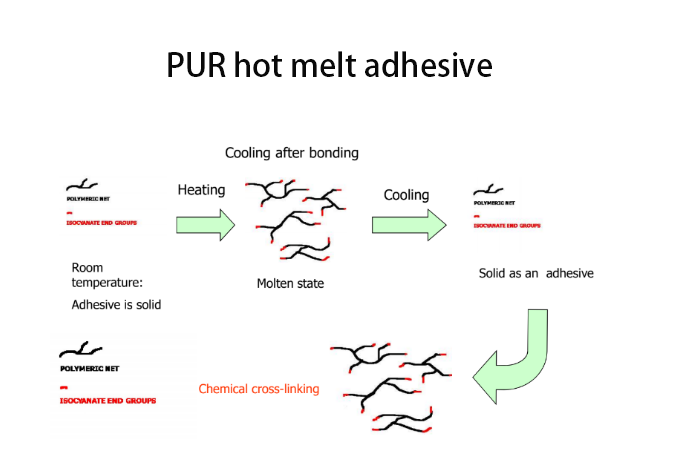

2. Curing Mechanism of PUR Hot Melt Adhesive

The curing process of PUR hot melt adhesive can be divided into three stages:

(1) Melting Stage

Like conventional hot melt adhesive, PUR hot melt adhesive melts when heated (typically between 100-120°C), becoming a liquid suitable for application. At this stage, the adhesive flows smoothly, ensuring even coverage on bonding surfaces.

(2) Moisture-Activated Curing Stage

After application, PUR hot melt adhesive reacts with ambient moisture (humidity). The isocyanate groups (-NCO) in its molecular chains react with water (H₂O), forming a polyurea structure and releasing carbon dioxide (CO₂). This reaction causes cross-linking, creating a three-dimensional network that significantly enhances bond strength.

(3) Full Curing Stage

After 24-72 hours (depending on humidity levels), the adhesive fully cures, reaching maximum bonding strength. Due to chemical cross-linking, it offers far better heat resistance, solvent resistance, and aging resistance than standard hot melt adhesives.

3. How Does PUR Hot Melt Adhesive Achieve Ultra-Strong Bonding?

The exceptional bonding strength of PUR hot melt adhesive comes from the following factors:

(1) Chemical Cross-Linking Structure

Unlike conventional hot melt adhesives that solidify only through physical cooling, PUR hot melt adhesive forms a cross-linked network via chemical reactions, providing superior cohesive and adhesive strength to withstand greater mechanical stress.

(2) Excellent Wetting Ability

In its molten state, PUR hot melt adhesive has very low surface tension, allowing it to fully wet substrate surfaces and even penetrate microscopic pores, increasing the bonding area and adhesion force.

(3) Environmental Resistance

Thanks to the chemical stability of polyurethane hot glue, the cured adhesive layer resists high temperatures (up to 120°C+), oils, solvents, and UV radiation, making it suitable for harsh environments.

(4) Balance of Flexibility and Toughness

Once cured, PUR hot melt adhesive offers both elasticity (to absorb vibrations and impacts) and rigidity (to prevent cracking), making it ideal for dynamic load applications.

4. Applications of PUR Hot Melt Adhesive

Due to its outstanding performance, PUR hot melt adhesive is widely used in multiple industries:

(1) Automotive Manufacturing

Used in headlight assembly, interior bonding, and soundproofing material fixation, offering excellent heat and shock resistance.

(2) Electronics Encapsulation

Ideal for bonding and sealing precision components in smartphones, tablets, and circuit boards, ensuring long-term stability.

(3) Furniture & Woodworking

Used for high-end furniture edge banding and composite panel bonding, being solvent-free and environmentally friendly.

(4) Packaging Industry

Provides strong sealing for cartons and boxes, suitable for high-speed automated production lines.

(5) Footwear & Textiles

Used in sports shoe soles and waterproof fabric bonding, offering flexibility and durability.

Profile wrapping&Edge banding

Flat lamination

5. How to Choose the Right PUR Hot Melt Adhesive?

Different applications require different adhesive properties. Consider the following factors when selecting:

Substrate type (metal, plastic, wood, etc.)

Curing speed (fast or slow curing)

Temperature resistance (high or low-temperature environments)

Flexibility needs (high elasticity or rigidity)

Consulting a professional PUR hot melt adhesive manufacturer ensures optimal bonding performance.

6. Conclusion

PUR hot melt glue (polyurethane reactive hot melt adhesive) achieves far greater bonding strength and environmental resistance than tradit HMAs through its unique moisture-curing mechanism. Its chemical cross-linking, excellent wetting ability, and heat resistance make it an ideal choice for high-performance bonding applications. As technology advances, more industries are adopting polyurethane hot glue, pushing bonding technology to new heights.

If you're looking for a high-performance bonding solution, consider PUR hot melt adhesive and collaborate with a trusted supplier for the best results! Please feel free to contact us for more professional information. Thanks.

Guangzhou R&D center

Guangzhou R&D center