How to Better Use PUR Hot Melt Adhesive

Introduction

PUR (Polyurethane Reactive) hot melt adhesive is a versatile and powerful bonding solution widely used in various industries, including woodworking, packaging, and automotive. Its unique properties, such as excellent adhesion, durability, and resistance to temperature and moisture, make it a preferred choice for many applications. In this article, we’ll explore effective strategies to optimize the use of PUR hot melt adhesive, ensuring stronger bonds and improved efficiency.

Understanding PUR Hot Melt Adhesive

PUR hot melt glue is a one-component adhesive that reacts with moisture in the air to form a strong, durable bond. Unlike traditional hot melt adhesives, which require high temperatures for application and cool quickly, PUR adhesives maintain flexibility and strength over time, making them ideal for demanding environments.

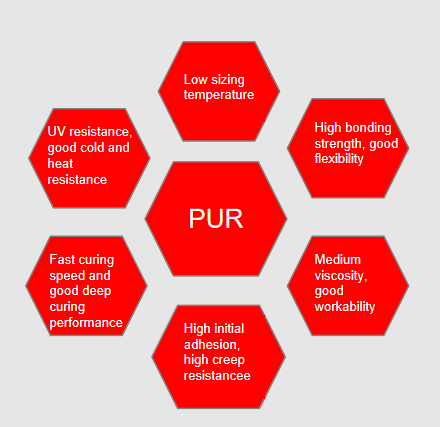

Key Benefits of PUR Adhesive

High Bond Strength: PUR adhesives provide superior adhesion to a variety of substrates, including wood, plastics, and metals.

Durability: They offer excellent resistance to heat, cold, and moisture, making them suitable for both indoor and outdoor applications.

Versatility: Suitable for a wide range of materials and applications, from furniture assembly to packaging.

Tips for Optimizing the Use of PUR Hot Melt Adhesive

1. Proper Surface Preparation

To ensure optimal bonding, surfaces must be clean, dry, and free from contaminants. Consider the following:

Cleaning: Remove dust, grease, and other residues using appropriate cleaning agents.

Sanding: For wooden surfaces, lightly sanding can enhance adhesion by increasing the surface area.

2. Control Application Temperature

The application temperature of PUR hot melt adhesive is crucial. Follow these guidelines:

Recommended Temperature: Typically, a temperature range of 120-160°C (248-320°F) is ideal. Adjust based on specific product recommendations.

Avoid Overheating: Excessive heat can degrade the adhesive properties, so monitor the temperature closely.

3. Optimize Application Techniques

Using the right application technique can significantly improve bonding efficiency:

Bead Size: Use a consistent bead size to ensure even distribution and adequate coverage.

Pressing Time: Apply sufficient pressure for a consistent duration to enhance bond strength.

Joint Design: Design joints that maximize surface area for better adhesion.

4. Consider Environmental Conditions

PUR adhesives are sensitive to environmental factors:

Humidity: Higher humidity levels can accelerate the curing process, while low humidity can slow it down. Monitor conditions and adjust application accordingly.

Temperature Variations: Ensure that materials and the adhesive are at similar temperatures before application to prevent thermal shock.

5. Storage and Handling

Proper storage and handling can prolong the life of PUR adhesives:

Storage Conditions: Keep adhesives in a cool, dry place, away from direct sunlight and extreme temperatures.

Shelf Life: Check the manufacturer's guidelines for shelf life and usage after opening.

6. Regular Maintenance of Equipment

To ensure consistent performance, maintain application equipment regularly:

Clean Nozzles: Clogged nozzles can affect adhesive flow and application consistency.

Check Temperature Settings: Regularly calibrate temperature settings to ensure optimal performance.

Conclusion

By following these strategies, you can maximize the effectiveness of PUR hot melt adhesive in your projects. Proper surface preparation, temperature control, and application techniques are key to achieving strong, durable bonds. Whether you’re in woodworking, packaging, or any other industry, optimizing your use of PUR adhesives will lead to improved product quality and efficiency.

Incorporating these practices will not only enhance the performance of your bonding applications but also contribute to overall project success. For more information on PUR hot melt adhesives and their applications, please feel free to CONTACT US Confay adhesive a professional adhesive supplier! Our professional team of technical solution will be your strongest back up.