How to Test PUR Hot Melt Adhesive for Woodworking Flat Lamination?

In the woodworking industry, PUR hot melt adhesive (polyurethane reactive hot melt adhesive) has become the preferred bonding material for flat lamination processes due to its exceptional bonding strength, heat resistance, and waterproof properties. As a high-performance PUR hot melt adhesive, it forms strong chemical bonds through moisture-curing reactions, making it suitable for various wood and membrane lamination applications. This article provides a detailed analysis of the entire PUR hot melt adhesive flat lamination testing process, helping woodworking enterprises and PUR adhesive manufacturers optimize application processes and ensure product quality. The testing process strictly follows industry standards, covering flowability inspection, lamination uniformity, curing effect, and strength evaluation, aiming to verify the practical performance of PUR hot melt adhesive for woodworking.

Test Preparation and Initial Steps

Before testing begins, ensure stable environmental conditions with temperature controlled at 20-25°C and humidity at 50-60% to avoid external interference. Select standard woodworking panels and compatible membranes as test samples. The PUR hot melt glue needs to be preheated in specialized melting equipment, waiting for the adhesive to completely melt. This step is crucial, as incomplete melting may lead to poor flowability or incomplete curing, affecting the final bonding effect. During the melting process, monitor the adhesive temperature to ensure it remains within the range recommended by PUR adhesive manufacturers (typically 110-130°C). Once the adhesive reaches the ideal state, proceed to the flowability observation phase.

Flowability is a key indicator for evaluating whether the PUR hot melt adhesive is suitable for application. Visually inspect the flow of the adhesive in the container - the ideal state should be uniform and smooth, without lumps or bubbles. If flowability is insufficient, temperature adjustment or batch replacement might be necessary. This step directly affects the uniformity of subsequent adhesive application, thereby influencing the flatness and durability of woodworking products.

Adhesive Application and Lamination Process

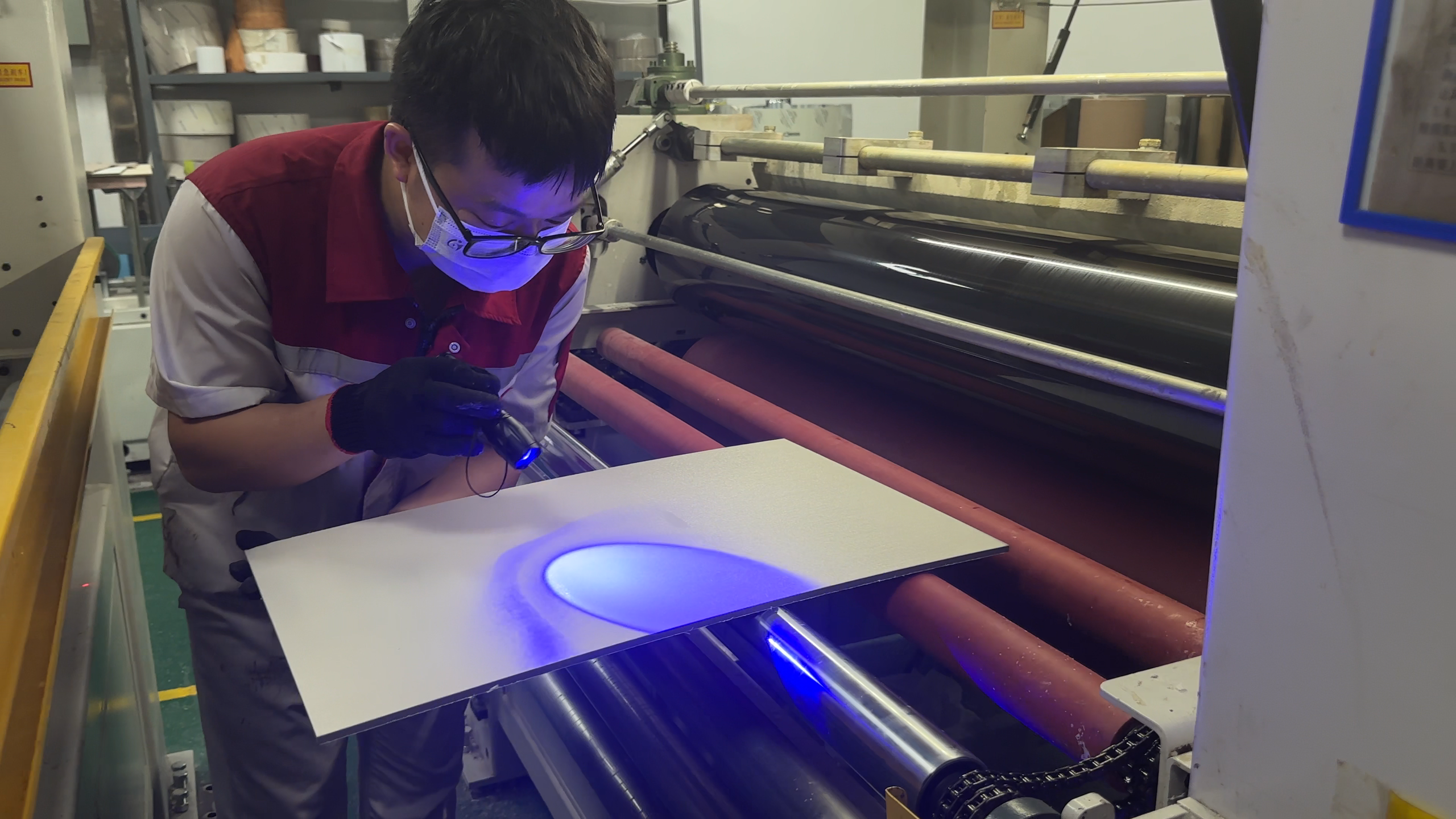

Remove the preheated panels from the 45°C high-temperature oven, weigh them, and record initial data. This weighing step helps quantify adhesive usage, ensuring consistency. Begin adhesive application using either automatic coaters or manual tools to evenly apply PUR hot melt glue, with adhesive thickness typically controlled between 0.1-0.3mm, adjusted according to panel type and membrane material. After application, immediately use a flashlight to check whether the adhesive is evenly distributed. Under light inspection, any uneven areas (such as missing adhesive or accumulation) will be visible, requiring immediate adjustment to prevent bubbling or edge lifting.

Next, proceed with membrane lamination, applying appropriate pressure to ensure tight contact. After lamination, again use light to observe the stringing condition between the membrane and adhesive layer. The stringing test is an intuitive method to evaluate the tackiness of PUR hot melt adhesive: longer strings indicate stronger tackiness, demonstrating that the adhesive has formed strong initial tack in the early stage. This characteristic is particularly important for woodworking applications as it prevents membrane displacement before curing, improving production efficiency. Record string length and uniformity as references for subsequent analysis.

Curing and Conditioning Stage

Return the laminated panels to the 45°C oven for constant-temperature conditioning for 24 hours. This step is core to the curing of polyurethane reactive hot melt adhesive, where moisture triggers cross-linking reactions to form irreversible chemical bonds. The conditioning environment must remain stable, with temperature fluctuations not exceeding ±2°C, to ensure uniform curing. During this period, the adhesive transitions from thermoplastic to thermosetting, significantly improving weather resistance and mechanical strength. The superiority of PUR hot melt adhesive for woodworking becomes apparent at this stage, as its high heat resistance can withstand thermal expansion and contraction in daily use of wood products.

After 24 hours, remove the samples and first conduct visual inspection to check whether the membrane surface shows issues like bubbling or edge lifting. Any defects may indicate improper adhesive application or unsuitable environmental conditions. For example, bubbling often stems from uneven adhesive distribution or moisture intrusion, while edge lifting may result from incomplete curing. This preliminary inspection serves as the first line of quality control, helping identify problems and adjust processes promptly.

Final Evaluation: Pull Test and Effect Analysis

The final stage comprehensively evaluates bonding strength and lamination effect through pull tests and visual inspection. Use a tensile machine to perform peel tests on samples, measuring the adhesive layer's performance under different stresses. Ideal PUR hot melt adhesive should demonstrate high cohesive strength, meaning the membrane or wood itself fractures during testing rather than adhesive layer separation. Simultaneously, visually inspect the lamination interface to confirm absence of bubbles, wrinkles, or discoloration. Data analysis combined with initial weight records can calculate adhesive efficiency, such as bonding strength per unit area.

Test results show that high-quality polyurethane reactive hot melt adhesive can achieve strength exceeding that of the wood itself in woodworking applications, ensuring long-term durability. PUR adhesive manufacturers often optimize product formulas based on such tests, such as adjusting open time or curing speed to accommodate different woodworking needs. Finally, the test report summarizes the adhesive's suitability, providing reference standards for the industry.

Conclusion

PUR hot melt adhesive flat lamination testing is a systematic process where every step - from adhesive melting to final strength evaluation - relates to the quality of woodworking products. By strictly following this process, enterprises can ensure maximum effectiveness of PUR hot melt glue in flat lamination applications, reducing defect rates and enhancing customer satisfaction. For PUR adhesive manufacturers, such testing forms the foundation of product development and quality control, driving the industry toward high performance and environmental sustainability. In the future, with advancements in woodworking technology, PUR hot melt adhesive for woodworking will continue to innovate, empowering green manufacturing and efficient production.

In summary, PUR hot melt adhesive testing not only verifies its reliability as a polyurethane reactive hot melt adhesive but also provides practical guidance for woodworking enterprises. Through scientific methods and careful observation, we can maximize bonding effectiveness and support industry upgrading.

Have Any Adhesive Questions ? Please kindly feel free to contact us for more information.

More than 15 years of experience to answer your questions!