What Glue to Use for Laminating Wood?

When it comes to wood laminating projects, choosing the right adhesive is crucial for achieving strong, durable bonds that stand the test of time. Among the various options available, PUR hot melt adhesive has emerged as the premier choice for professional woodworkers and manufacturers. This comprehensive guide explores why hot melt adhesive technologies, particularly polyurethane reactive hot melt adhesive, have become the gold standard in wood laminating applications.

PUR hot melt adhesive

PUR hot melt adhesive

Understanding Wood Lamination Adhesives

Wood lamination involves bonding multiple layers of wood or wood products together to create composite materials with enhanced strength, stability, and aesthetic appeal. The adhesive used in this process must meet several critical requirements:

Strong initial tack for immediate bonding

Excellent final bond strength

Resistance to environmental factors (temperature, humidity)

Compatibility with various wood species

Appropriate open time for assembly

Traditional wood glues like PVA (polyvinyl acetate) have been used for decades, but modern manufacturing demands have led to the development of superior hot melt glue for flat lamination machine applications that offer significant advantages in production environments.

PUR hot melt adhesive

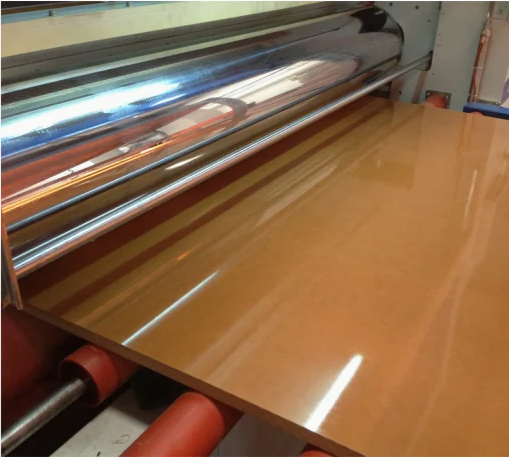

Flat lamination

Why PUR Hot Melt Adhesive Stands Out

PUR hot melt glue represents a significant advancement in adhesive technology for wood laminating. Unlike conventional hot melt adhesives that simply cool to form bonds, polyurethane reactive hot melt adhesive undergoes an additional chemical curing process that creates exceptionally strong, permanent bonds.

Key Advantages of PUR Hot Melts:

1.Superior Bond Strength: PUR adhesives form bonds that are often stronger than the wood itself

2.Excellent Temperature Resistance: Withstands temperatures from -40°F to +200°F (-40°C to +93°C)

3.Moisture Resistance: Unlike PVA glues, PUR bonds remain stable in humid conditions

4.Versatility: Bonds well with various wood types, including hardwoods, softwoods, and engineered wood products

5.Clean Application: Minimal stringing and clean processing in automated systems

Hot Melt Adhesive Types for Wood Laminating

1. Standard Hot Melt Adhesives

Traditional hot melt adhesive products are thermoplastic materials that melt when heated and solidify upon cooling. While these work for some temporary or light-duty applications, they lack the durability needed for most wood laminating projects.

2. Polyurethane Reactive (PUR) Hot Melt Adhesives

Polyurethane reactive hot melt adhesive represents the premium choice for professional wood laminating. These adhesives combine the immediate bonding capability of hot melts with a secondary curing process where the adhesive reacts with moisture in the air to form permanent, cross-linked bonds.

Applications of PUR Hot Melt in Wood Lamination

PUR hot melt glue excels in various wood laminating scenarios:

Flat panel lamination: Ideal for hot melt glue for flat lamination machine setups in furniture manufacturing

Edge banding: Provides durable edges for plywood and particleboard

Veneer laminating: Bonds thin veneers to substrates without bleed-through

Solid wood laminating: Creates strong joints for tabletops, countertops, and beams

Composite wood products: Excellent for MDF, HDF, and particleboard applications

How to Apply PUR Hot Melt for Wood Laminating

Proper application is key to achieving optimal results with PUR hot melt adhesive:

1.Surface Preparation: Ensure wood surfaces are clean, dry, and free from dust or oils

2.Temperature Control: Maintain adhesive at recommended application temperature (typically 250-300°F/120-150°C)

3.Application Method: Use specialized applicators designed for hot melt glue for flat lamination machine systems

4.Open Time Management: Assemble components within the adhesive's open time (typically 30-90 seconds)

5.Pressure Application: Apply sufficient pressure during curing (clamping or mechanical pressure)

6.Curing Time: Allow full cure (24 hours for complete cross-linking)

Comparing PUR to Other Wood Laminating Adhesives

Adhesive Type | Bond Strength | Water Resistance | Temperature | Open Time | Ease of Use |

PVA Glue | Good | Fair | Poor | Long | Easy |

Epoxy | Excellent | Excellent | Excellent | Medium | Difficult |

Contact Cement | Good | Good | Fair | Short | Moderate |

PUR Hot Melt | Excellent | Excellent | Excellent | Medium | Moderate |

Technical Specifications of PUR Hot Melt Adhesives

High-quality polyurethane reactive hot melt adhesive products typically offer:

Viscosity: 10,000-30,000 cP at application temperature

Application Temperature: 250-300°F (120-150°C)

Open Time: 30-90 seconds (varies by formulation)

Tensile Strength: 3,000-5,000 psi

Shore Hardness: 70-90D (after full cure)

Density: 1.1-1.3 g/cm³

Flat lamination glue

Flat lamination

Choosing the Right PUR Hot Melt for Your Project

When selecting a PUR hot melt glue for wood laminating, consider:

1.Substrate Materials: Different formulations for hardwoods vs. softwoods

2.Production Speed: Faster curing formulas for high-speed operations

3.Environmental Conditions: Special formulations for extreme climates

4.pplication Equipment: Compatibility with your hot melt glue for flat lamination machine

5.Regulatory Requirements: Compliance with relevant safety standards

Maintenance and Storage of PUR Hot Melt Adhesives

To ensure optimal performance of your hot melt adhesive:

Store unopened containers in cool, dry conditions

Once opened, use promptly or reseal with nitrogen blanket

Maintain clean application equipment

Regularly purge systems to prevent charring

Follow manufacturer's recommendations for pot life

Troubleshooting Common PUR Hot Melt Issues

Problem: Poor bond strength

Solution: Check surface preparation, ensure proper application temperature

Problem: Short open time

Solution: Adjust room humidity, use slower-curing formulation

Problem: Excessive stringing

Solution: Optimize application temperature, use anti-stringing additives

Problem: Crystallization in reservoir

Solution: Maintain proper temperature control, avoid contamination

Environmental and Safety Considerations

While PUR hot melt adhesive offers excellent performance, proper handling is essential:

Use in well-ventilated areas

Wear appropriate PPE (gloves, eye protection)

Follow manufacturer's MSDS guidelines

Dispose of unused adhesive properly

Consider low-VOC formulations for indoor applications

The Future of Wood Laminating Adhesives

The adhesive industry continues to innovate, with developments in:

Bio-based polyurethane reactive hot melt adhesive formulations

Faster-curing PUR hot melt glue products

Improved temperature-resistant formulas

Smart adhesives with moisture-indicating properties

Enhanced compatibility with recycled wood materials

Conclusion

For professional wood laminating applications, PUR hot melt adhesive stands as the superior choice, offering unmatched bond strength, durability, and versatility. Whether you're working with a small shop setup or an industrial hot melt glue for flat lamination machine system, investing in high-quality polyurethane reactive hot melt adhesive will ensure your laminated wood products meet the highest standards of quality and performance.

By understanding the properties, applications, and proper handling of PUR hot melt glue, woodworking professionals can achieve consistent, reliable results in all their laminating projects. As adhesive technology continues to advance, these innovative products will undoubtedly remain at the forefront of wood laminating solutions.

Please feel free to contact us for more professional information. Thanks.