The Application Advantages of PUR Hot Melt Adhesive in Profile Wrapping

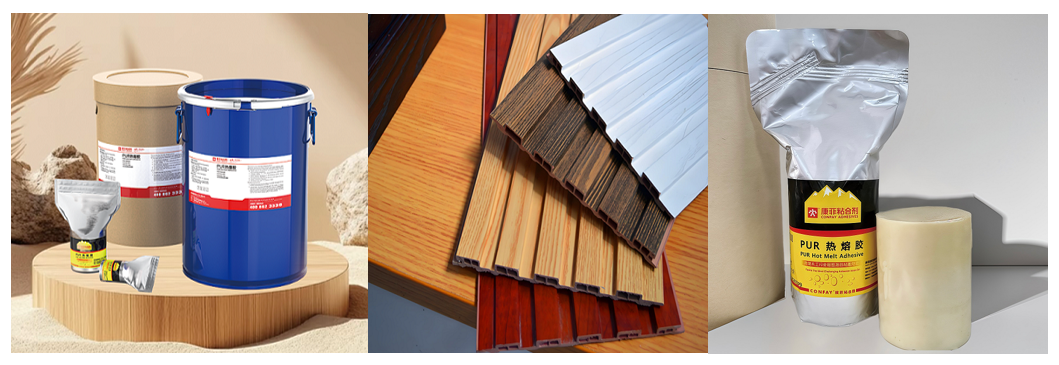

In the woodworking industry, profile wrapping is a technically demanding process, especially in the manufacturing of high-end products such as furniture, wooden doors, and decorative moldings. PUR hot melt adhesive for profile wrapping has become the preferred adhesive due to its excellent bonding performance and process adaptability. This article will explore the application advantages of PUR hot melt adhesive in profile wrapping to help you better understand this efficient solution.

1. Excellent Bonding Strength

PUR hot melt adhesive offers high initial tack and ultimate bonding strength, ensuring a firm bond on various profile surfaces, including wood, PVC, and acrylic. Its unique chemical curing properties create a strong and durable bonding interface after curing, effectively preventing issues such as delamination and cracking, thereby ensuring long-lasting wrapping results.

2. Outstanding Flexibility and Adaptability

Profiles often feature complex curves and angles, which place high demands on the flexibility of the adhesive. PUR hot melt adhesive for profile wrapping retains a certain level of elasticity after curing, allowing it to adapt to the deformation of profiles and avoid cracking caused by temperature changes or external forces. Whether it’s right angles, arcs, or complex curves, PUR hot melt adhesive can achieve seamless wrapping.

3. Efficient Application Performance

PUR hot melt adhesive for profile wrapping has a long open time, making it easier for operators to adjust material positions during the wrapping process to ensure precise alignment. At the same time, its rapid curing significantly shortens production cycles and improves efficiency. Additionally, PUR hot melt adhesive is compatible with automated wrapping equipment, meeting the needs of large-scale production.

4. Excellent Weather Resistance and Environmental Friendliness

Profile-wrapped products are often used in both indoor and outdoor environments, requiring adhesives with high weather resistance. PUR hot melt adhesive offers excellent resistance to water, heat, and low temperatures, maintaining stable bonding performance even in extreme conditions. Moreover, PUR hot melt adhesive is solvent-free and complies with environmental standards, providing users with a safe and healthy experience.

5. Wide Range of Applications

PUR hot melt adhesive for profile wrapping is suitable for various profile wrapping scenarios, such as door wrapping, cabinet decorative moldings, and furniture edge banding. Whether for flat or curved surfaces, simple or complex structures, PUR hot melt adhesive provides reliable bonding solutions to meet diverse production needs.

Conclusion

PUR hot melt adhesive for profile wrapping, with its excellent bonding strength, flexibility, application performance, and environmental benefits, has become the ideal choice for profile wrapping. It not only enhances product quality but also helps enterprises improve production efficiency and reduce overall costs. If you are looking for an efficient and reliable solution for profile wrapping, PUR hot melt adhesive is undoubtedly your best choice.

For more information on PUR adhesive for profile wrapping and its benefits, contact us today!